Premium Label Printing

Premium digital and flexographic printing services tailored to mid-to-large businesses. Large-volume printing and short-run test prints available. Fulfilled by Consolidated Label Co., a division of Online Labels Group.

Printing Solutions for Your Business

Learn more about popular industries we serve along with our professional printing capabilities, materials, and finishes. We'll tailor any order to your project. Can't find what you need below?

Let's connect!

- Custom Fruit & Produce Labels

- Consecutive Number Labels

- Custom Juice Labels

- Custom Tube Labels

- Custom Vial Labels

- Custom Durable Labels

- Custom Coupon Labels

- Custom Condiment & Sauce Labels

- Custom Nutraceutical & Supplement Labels

- Custom Vitamin Labels

- Custom Pharmaceutical Labels

- Custom Multi-Layer Labels

- Custom Piggyback Labels

- Labels for Co-Packers

- Custom Brown Kraft Labels

- Custom Clear Labels

- Custom Fluorescent Labels

- Custom Metallic / Foil Labels

- Custom Removable Labels

- Custom Film / Bopp Labels

- Custom Holographic Labels

- Custom Squeezable Film Labels

- Custom Vinyl Labels

- High-Gloss Label Finish

- Cold-Foil Stamping

- Matte Label Finish

- Polyester-Laminated Labels

Let's bring your ideas to life.

Get the look you want with our wide selection of materials and specialty coatings like UV protections, dual & spot coatings, and more. Or, go beyond labels with specialty shrink sleeves and flexible packaging.

-

State-of-the-art flexographic and digital presses

-

Large variety of stocks and adhesives in-stock

-

Experienced support team on-location for exceptional service

Looking to switch suppliers? We can match what you have, and make it better.

Pressure Sensitive Labels

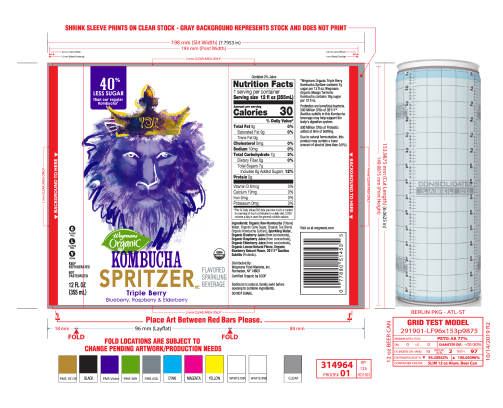

Shrink Sleeves

Flexible Packaging

It's ensured at every step.

Our quality assurance team inspects your labels through the entire printing process, checking for things like readability, barcode scannability, and print quality.

-

We're ISO 9001:2015 registered, meaning we conform to a quality management system based on a process-based approach to continual improvement.

-

18-time winner of the Eugene Singer award for our dedication to business development and management.

-

We're also a proud member of Sedex, an organization dedicated to ethical trade and sourcing practices.

Endless options to match your vision.

-

Sophisticated color matching and 12-color printing capability equips us for any job.

-

On-site SpectroDensitometers for accurate scientific color matching and color-blending capabilities.

-

We're GMI (Graphic Measures International) certified in color matching accuracy on our flexographic and digital printing presses. You can beconfident in our standards for color reproduction.

Graphic Measures International Certified Print Facility

Solutions that go above industry standards.

-

Over 30 years of experience working with private label brands has given us a unique perspective into the market. That translates into a smooth process for you.

-

Specialty labeling products like shrink sleeves, multi-layer labels, and variable data options streamline the labeling process for any container type.

-

Create additional value for your customers with high-quality labels and packaging.

"The consolidated team has been extremely responsive and solutions oriented. Their sales, customer service and art/creative teams worked collaboratively and seamlessly with my management, design agency and copacker to achieve desired results within tight timetables."

Chris New, Chief Executive Officer

Cyclone Products, LLC

We're here to help.

Our focus is to figure out your needs and make the label ordering process as seamless as possible, so you end up with the results you envisioned.

-

When you work with us, you get direct access to a designated sales rep as well as a dedicated team of label experts.

-

Fast response times, connections & resources in your industry, and a deep knowledge of packaging solutions differentiate us from the competition.

-

Your account rep will work with you directly to ensure all of your deadlines are met. Production runs 24/7, so we can cater to even the tightest of deadlines.

"My first experience ordering from Consolidated Label Co. was excellent. As a small start-up business owner, it was a blessing to have experienced help through the ordering process from my customer service rep. Also, I was very impressed with the printing quality of the labels when I received them; the details were crystal clear and looked great."

Timothy Potter, Chief Executive Officer

Timothy J. Potter Music Co.

*Source: Reviews.io - Consolidated Label Co. Reviews

Over 700 Positive Reviews (4.8/5.0)

98% of Reviewers Recommend Us

100% On-time Delivery

Ready to share your vision?

Frequently Asked Questions

-

What's the difference between flexographic printing and digital printing?

Both our flexographic and digital printing presses produce the highest quality graphics.

Flexographic printing is a long-proven process that adds ink one color at a time to a substrate using flexible printing plates. The plates use a series of dots to transfer the ink. If you zoom in closer than the eye can see, you can see them in the makeup of your image, but our HD Flexo technology produces near photo-realistic imagery to the naked eye. This printing process is good for longer print runs because the small up-front setup costs outweigh the efficiency over time.

Digital printing is a younger method than flexographic, but has come a long way in relatively few years. While it's always been good for short runs and variable data or consecutive numbering, it's now becoming a go-to technology for jobs with multiple versions of the same size label as well as jobs that require photo-realistic imagery and extreme tolerances in the graphics.

-

What does it mean to be an ISO 9001:2015 certified company?

This certification means that we conform to the latest quality process standards set by the International Standards Organization (ISO).

ISO 9001:2015 identifies requirements for a quality management system based on the company's ability to provide products consistently in a manner that meets customer and regulatory requirements, as well as the aim of enhancing customer satisfaction through application and improvement of the system.

In short, this certification proves reliability, efficient and effective processes, and the ability to exceed expectations on a consistent basis.

-

Can you print variable data?

Yes. We have the ability to print different information on the same run of labels using the latest digital press management software. Whether you need consecutive or serial numbering, varying designs for a single product on a roll, or varying QR codes, we can make that happen. Our prepress team will work with you to make sure we have everything we need to get the results you want.

-

Can I send in something for you to color match on press?

Yes. We work with you by either choosing a Pantone color that's a close match, or by working from a physical sample of the exact color, whether it be a container, paint chip, or sample from another item in your product line. We understand the importance of having accurate colors, so we have the tools necessary to achieve an exact color match for labels, shrink sleeves, and flexible packaging.

We have an on-site ink department that creates samples for your approval on the material you've chosen to use for your labels. We use two different color matching processes: 4 color process printing and spot color printing. Four color process printing creates colors by building on layers of CMYK inks to achieve full-color results. Spot color printing is more accurate and can accurately reproduce colors that are outside the scope of 4 color process printing.

-

Do you provide samples and proofs?

Our standard practice for all new projects is to provide a digital proof for approval before sending it to press. Once you receive the proof, you can verify the size, shape, and content (spelling and graphics), then submit any revisions so that we can make adjustments before moving the project to press.

Verifying these details allows us to get your order to you correctly the first time, avoiding unnecessary delays and time spent reprinting while you need your labels.

We're happy to provide samples of materials or previously printed work at your request. Just fill out the form and let us know that you're interested in samples, and one of our sales representatives will reach out to you.

-

Can I add texture to shrink sleeves?

Yes — and if you're in the market for shrink sleeves, adding texture is a unique decoration that can set you apart from the rest. This process requires the purchase of a special print cylinder that's unique to you and can be used over and over again on all orders of that same design.

We add texture by using a Rotary Screen Integration (RSI®) system which has the capability to create:

- Raised ink deposits

- Finely detailed lines and shapes

- Tactile raised images

- Hologram imitations

- 3D effects

- Security features